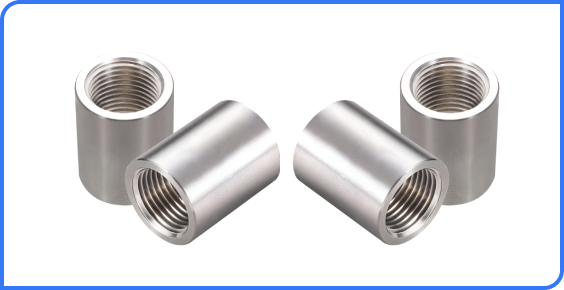

Threaded Socket

What is a Threaded Socket?

A Threaded Socket, also referred to as a Threaded Coupling, is a short pipe fitting used to connect two pipes of the same or different sizes via female threads. Designed for low to medium-pressure piping systems, these fittings allow for easy and secure straight-line pipe connections without welding.

Threaded sockets are commonly used in water pipelines, oil & gas networks, fire protection systems, and compressed air lines, and are available in full, half, and reducing types to suit various piping layouts.

Key Features

Leak-Proof

Jointing

Durable

Construction

Easy Installation

& Removal

Wide

Compatibility

Corrosion

Resistant

Specifications

| Specification Category | Parameter / Feature |

|---|---|

| Size Range | Nominal Size |

| Pressure Ratings | ANSI / ASME Class |

| PN Ratings | |

| Product Types | Threaded Socket |

| Material Options | Carbon Steel |

| Stainless Steel |

Dimensions

| Fitting Type | Nominal Size (NPS) | Outside Diameter (OD) | Wall Thickness (Schedule) | Length (L) | End Connections | Weight per Piece |

|---|---|---|---|---|---|---|

| Threaded Socket | ½” | 21.3 mm | Schedule 40, Schedule 80 | 40 mm | Threaded (NPT, BSP, BSPT, PT) | 200g |

| Threaded Socket | ¾” | 26.7 mm | Schedule 40, Schedule 80 | 50 mm | Threaded (NPT, BSP, BSPT, PT) | 250g |

| Threaded Socket | 1″ | 33.4 mm | Schedule 40, Schedule 80 | 60 mm | Threaded (NPT, BSP, BSPT, PT) | 350g |

| Threaded Socket | 1½” | 48.3 mm | Schedule 40, Schedule 80 | 70 mm | Threaded (NPT, BSP, BSPT, PT) | 550g |

| Threaded Socket | 2″ | 60.3 mm | Schedule 40, Schedule 80 | 80 mm | Threaded (NPT, BSP, BSPT, PT) | 800g |

| Threaded Socket | 2½” | 73.0 mm | Schedule 40, Schedule 80 | 100 mm | Threaded (NPT, BSP, BSPT, PT) | 1.0kg |

| Threaded Socket | 3″ | 88.9 mm | Schedule 40, Schedule 80 | 120 mm | Threaded (NPT, BSP, BSPT, PT) | 1.5kg |

| Threaded Socket | 4″ | 114.3 mm | Schedule 40, Schedule 80 | 140 mm | Threaded (NPT, BSP, BSPT, PT) | 2.0kg |

Mechanical Properties

| Property | Value | Unit / Standard |

|---|---|---|

| Tensile Strength | 485 – 750 | MPa (Carbon Steel, Stainless Steel, Alloy Steel) |

| Yield Strength | 170 – 450 | MPa |

| Hardness | 120 – 200 | HB (Brinell) |

| Elongation | ≥ 20 – 30 | % |

| Density | 7.8 – 8.0 | g/cm³ (Carbon Steel), 7.9 – 8.0 g/cm³ (Stainless Steel) |

| Impact Toughness | ≥ 27 – 70 | J (Charpy, grade-dependent) |

| Modulus of Elasticity (E) | ~200 | GPa |

| Fatigue Strength | 250 – 450 | MPa |

| Corrosion Resistance | Good to Excellent (SS > CS > Alloy Steel) | – |

| Thermal Conductivity | 15 – 50 | W/m·K |

| Coefficient of Thermal Expansion | 11 – 17 ×10⁻⁶ | /°C |

| Yield Ratio (YS/UTS) | 0.40 – 0.65 | – |

| Poisson’s Ratio | 0.27 – 0.30 | – |

| Brinell Hardness Range | 120 – 200 | HB |

| Surface Finish | Serrated / Stock / Smooth finish per ASME B16.11 | – |

| Threading Type | Threaded Connection (NPT, BSP, BSPT, PT) | – |

| Operating Temperature Range | -46 to 600 | °C (material-dependent) |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500 | ASME B16.11 |

Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.08 – 0.35 |

| Manganese (Mn) | 0.60 – 1.65 |

| Silicon (Si) | 0.15 – 0.80 |

| Chromium (Cr) | 18.0 – 20.0 (Stainless Steel) |

| Nickel (Ni) | 8.0 – 10.5 (SS 304/316) |

| Molybdenum (Mo) | 2.0 – 3.0 (for F316 only) |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.040 |

| Iron (Fe) | Balance |

Applications of Threaded Sockets

Construction &

Infrastructure

Automotive & Heavy

Equipment

Manufacturing &

Fabrication

Medical & Laboratory

Equipment

Electrical &

Electronics Assembly

Oil, Gas & Petrochemical

Installations

Do you have questions?

A full coupling has threads on both ends, while a half coupling has threads on one side and a plain end for welding or socketing.

Yes, we offer reducing couplings to connect pipes of differing diameters.

We provide NPT, BSP, BSPT, and custom threads as per client needs.

Yes, provided the threads are undamaged and properly sealed during reassembly.