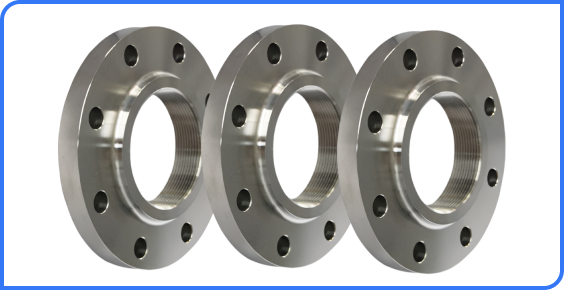

Threaded Flanges

What are Threaded Flanges?

Threaded Flanges are pipe connection components that feature a tapered internal thread, allowing pipes to be screwed directly into the flange without the need for welding. These flanges are ideal for low-pressure, non-critical applications or in environments where welding is hazardous or impractical.

Asiad Steel Industries is a prominent manufacturer and supplier of premium-quality Threaded Flanges in stainless steel, carbon steel, and special alloys for various global industries.

Key Features

Strong &

Reliable Connection

Durable

Construction

Easy Installation

& Removal

Wide

Compatibility

Corrosion

Resistant

Specifications

| Specification Category | Parameter / Feature | Description / Options |

|---|---|---|

| Size Range | Nominal Pipe Size (NPS) | ½” to 24” (DN15 – DN600), Custom sizes available on request |

| End-to-End Dimensions | Standard per ASME/ANSI, tolerances ±1% | |

| Pressure Class | ANSI / ASME Class | 150#, 300#, 600#; Other classes |

| PN Rating | PN6, PN10, PN16, PN25, PN40 | |

| Thread Types | Standard Threads | NPT, BSP, BSPT, ISO |

| Optional Custom Threads | Metric, UNF/UNC threads | |

| Facing Types | Standard Flange Faces | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Optional Faces | Tongue & Groove, Male-Female | |

| Materials | Carbon Steel | CS A105, CS A350 LF2 |

| Stainless Steel | SS 304, SS 304L, SS 316, SS 316L, SS 321 | |

| Duplex / Super Duplex | Duplex 2205, Super Duplex 2507 | |

| Alloy Steel & Specialty Metals | Inconel, Monel, Titanium, Nickel Alloys | |

| Manufacturing Process | Forging & Heat Treatment | Forged, Annealed, Normalized, Quenched & Tempered |

| Machining & Finishing | CNC Machined, Polished, Passivated | |

| Welding Capability | Butt Weld, Socket Weld options available | |

| Standards & Compliance | ASME / ANSI | ASME B16.5, B16.47 |

| European Standards | EN 1092-1, BS 4504 | |

| Certifications | ISO 9001, PED 2014/68/EU, NACE MR0175 | |

| Coating & Surface Finish | Standard Coating | Rust preventive, Black oxide, Hot-dip galvanized |

| Optional Coatings | Epoxy, PTFE, Polyurethane | |

| Surface Finish | Machined, Polished, Passivated | |

| Connection Types | Mechanical Connections | Threaded, Lap Joint, Slip-On, Blind |

| Welding Connections | Butt Weld, Socket Weld | |

| Testing & Inspection | Pressure Testing | Hydrostatic, Pneumatic |

| Nondestructive Testing (NDT) | RT, UT, PT, MT | |

| Dimensional & Visual Inspection | Full inspection per ASME / EN standards | |

| Applications | Industries | Oil & Gas, Petrochemical, Water Treatment, Power, Shipbuilding, Chemical |

| Fluid Types | Water, Oil, Gas, Steam, Corrosive Liquids | |

| Tolerance & Traceability | Dimensional Tolerance | ±1% standard; ±0.5% for critical projects |

| Pressure & Rating Tolerance | As per ANSI/ASME Class standards | |

| Material Traceability | Mill Test Certificates (MTC) for all batches |

Class 400 (PN 68)

| NPS / DN | Drilling (mm) | No. of Holes | Dia. of Holes (mm) | Dia. of Bolt Circle (mm) | Bolt Dia. (Inches) | Length at Base (mm) | Length at Chamfer (mm) | Approximate Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 4” (DN100) | 8 | 1 | 7.88 / 200.0 | 7/8 | 5.5 / 140 | 6.0 / 153 | 5.75 / 146.1 | 0.37 |

| 5” (DN125) | 8 | 1 | 9.25 / 235.0 | 7/8 | 5.75 / 146 | 6.25 / 159 | 7.0 / 177.8 | 0.45 |

| 6” (DN150) | 12 | 1 | 10.62 / 269.7 | 7/8 | 6.25 / 159 | 6.5 / 165 | 8.12 / 206.4 | 0.61 |

| 8” (DN200) | 12 | 1.12 / 29 | 13.0 / 330.2 | 1 | 6.75 / 172 | 7.25 / 185 | 10.25 / 260.4 | 0.90 |

| 10” (DN250) | 16 | 1.25 / 32 | 15.25 / 387.3 | 1 1/8 | 7.5 / 191 | 8.0 / 204 | 12.62 / 320.7 | 1.35 |

| 12” (DN300) | 16 | 1.38 / 35 | 17.75 / 450.8 | 1 1/4 | 8.0 / 205 | 8.5 / 216 | 14.75 / 374.6 | 1.89 |

Class 600 (PN 100)

| NPS / DN | Drilling (mm) | No. of Holes | Dia. of Holes (mm) | Dia. of Bolt Circle (mm) | Bolt Dia. (Inches) | Length at Base (mm) | Length at Welding (mm) | Approximate Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 4” (DN100) | 8 | 1 | 1.00 / 26 | 8.50 / 216 | 7/8 | 6.00 / 152 | 6.5 / 165 | 0.44 |

| 5” (DN125) | 8 | 1 | 1.13 / 29 | 10.50 / 267 | 1 | 5.50 / 140 | 7.00 / 178 | 0.52 |

| 6” (DN150) | 12 | 1.13 / 29 | 11.50 / 292 | 1 | 7.00 / 178 | 7.5 / 191 | 8.75 / 222 | 0.95 |

| 8” (DN200) | 12 | 1.25 / 32 | 13.75 / 349 | 1 1/8 | 7.75 / 197 | 8.25 / 210 | 10.75 / 273 | 1.29 |

| 10” (DN250) | 16 | 1.38 / 35 | 17.00 / 432 | 1 1/4 | 8.75 / 222 | 9.25 / 235 | 13.50 / 343 | 1.80 |

| 12” (DN300) | 20 | 1.38 / 35 | 19.25 / 489 | 1 1/4 | 9.00 / 229 | 9.5 / 241 | 15.75 / 400 | 2.45 |

Class 900 (PN 150)

| NPS / DN | Drilling (mm) | No. of Holes | Dia. of Holes (mm) | Dia. of Bolt Circle (mm) | Bolt Dia. (Inches) | Length at Base (mm) | Length at Welding (mm) | Approximate Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 3” (DN80) | 8 | 1.00 | 7.50 | 7/8 | 6.0 | 6.5 | 5.00 | 0.34 |

| 4” (DN100) | 8 | 1.25 | 9.25 | 1 1/8 | 7.00 | 7.5 | 6.25 | 0.57 |

| 5” (DN125) | 8 | 1.38 | 11.00 | 1 1/4 | 7.50 | 8.00 | 7.50 | 0.68 |

| 6” (DN150) | 12 | 1.25 | 12.50 | 1 1/8 | 7.75 | 8.25 | 9.25 | 1.12 |

| 8” (DN200) | 12 | 1.50 | 15.50 | 1 3/8 | 9.00 | 9.5 | 11.75 | 1.43 |

| 10” (DN250) | 16 | 1.50 | 18.50 | 1 3/8 | 9.5 | 10.0 | 14.50 | 1.77 |

Class 1500 (PN 250)

| NPS / DN | Drilling (mm) | No. of Holes | Dia. of Holes (mm) | Dia. of Bolt Circle (mm) | Bolt Dia. (Inches) | Length at Base (mm) | Length at Welding (mm) | Approximate Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 1” (DN25) | 4 | 1.00 | 4.00 | 7/8 | 6.00 | 6.25 | 2.06 | 0.29 |

| 2” (DN50) | 8 | 1.00 | 6.50 | 7/8 | 6.00 | 6.50 | 4.12 | 0.60 |

| 3” (DN80) | 8 | 1.25 | 8.00 | 1 1/8 | 7.25 | 7.75 | 5.25 | 0.84 |

| 4” (DN100) | 8 | 1.38 | 9.50 | 1 1/4 | 8.00 | 8.50 | 6.38 | 1.05 |

| 5” (DN125) | 8 | 1.62 | 11.50 | 1 1/2 | 9.75 | 10.25 | 7.75 | 1.35 |

| 6” (DN150) | 12 | 1.50 | 12.50 | 1 3/8 | 10.50 | 11.00 | 9.00 | 1.72 |

Mechanical Properties

| Property | Value | Unit / Standard |

|---|---|---|

| Tensile Strength | 485 – 750 | MPa (varies with CS, SS, Alloy Steel) |

| Yield Strength | 170 – 450 | MPa |

| Hardness | 120 – 200 | HB (Brinell) |

| Elongation | ≥ 20 – 30 | % |

| Density | 7.8 – 8.0 | g/cm³ |

| Impact Toughness | ≥ 27 – 70 | J (Charpy, depending on grade) |

| Modulus of Elasticity (E) | ~200 | GPa |

| Fatigue Strength | 200 – 400 | MPa |

| Corrosion Resistance | Good to Excellent (grade-dependent) | – |

| Thermal Conductivity | 15 – 50 | W/m·K |

| Coefficient of Thermal Expansion | 11 – 17 ×10⁻⁶ | /°C |

| Yield Ratio (YS/UTS) | 0.45 – 0.65 | – |

| Poisson’s Ratio | 0.27 – 0.30 | – |

| Brinell Hardness Range | 120 – 200 | HB |

| Surface Finish | Serrated / Smooth / Stock Finish per ASME B16.5 | – |

| Thread Standards | NPT / BSP / BSPT | as per ASME B1.20.1 & ISO |

| Operating Temperature Range | -46 to 600 | °C (depends on material grade) |

| Pressure Rating | Class 150, 300, 600, 900, 1500 | ASME B16.5 Standards |

Chemical Composition

| Element | SS 304 (%) | SS 304L (%) | SS 316 (%) | SS 316L (%) |

|---|---|---|---|---|

| Chromium (Cr) | 18.0 – 20.0 | 18.0 – 20.0 | 16.0 – 18.0 | 16.0 – 18.0 |

| Nickel (Ni) | 8.0 – 10.5 | 8.0 – 12.0 | 10.0 – 14.0 | 10.0 – 14.0 |

| Carbon (C) | ≤ 0.08 | ≤ 0.03 | ≤ 0.08 | ≤ 0.03 |

| Manganese (Mn) | ≤ 2.00 | ≤ 2.00 | ≤ 2.00 | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 | ≤ 0.045 | ≤ 0.045 | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 |

| Iron (Fe) | Balance | Balance | Balance | Balance |

| Molybdenum (Mo) | — | — | 2.0 – 3.0 | 2.0 – 3.0 |

Applications of Threaded Flanges

Construction &

Infrastructure

Power Generation &

Energy Sector

Manufacturing &

Fabrication

Medical & Laboratory

Equipment

Electrical &

Electronics Assembly

Oil, Gas & Petrochemical

Installations

Do you have questions?

They are typically used in low-pressure systems, explosive environments, and temporary piping setups where welding is restricted.

Not recommended. They are best for Class 150 and Class 300 applications. For higher pressure, use Weld Neck Flanges or Socket Weld Flanges.

We offer NPT, BSP, BSPT, and ISO metric threads based on project requirements and regional standards.

Yes. We provide galvanized, epoxy-coated, PTFE-lined, and other corrosion-resistant finishes.