Copper Nickel

What is Copper Nickel?

Copper Nickel, also known as Cupronickel, is an alloy primarily composed of copper and nickel, with additions of iron and manganese to improve its strength and corrosion resistance. This alloy is widely valued for its excellent resistance to seawater corrosion, making it ideal for marine, desalination, and heat exchange applications.

Asiad Steel Industries is a reputed manufacturer and supplier of high-quality Copper Nickel alloys in a wide range of forms and grades.

Key Features

Thermal

Stability

Durable

Construction

Precision

Finish

Wide

Compatibility

Corrosion

Resistant

Specifications

| Specification Category | Parameter / Feature | Details / Options |

|---|---|---|

| Size Range | Nominal Size | 10 mm × 10 mm to 500 mm × 500 mm (custom sizes available) |

| Pressure Ratings | ANSI / ASME Class | Class 150, 300, 600, 900, 1500, 2500 |

| PN Ratings | PN6, PN10, PN16, PN25, PN40, PN64 | |

| Product Types | CuNi Pipes | ERW & Seamless, standard wall thickness |

| CuNi Sheets / Plates | 2B, Hot Rolled, Matt, Mirror Finish, Coloured | |

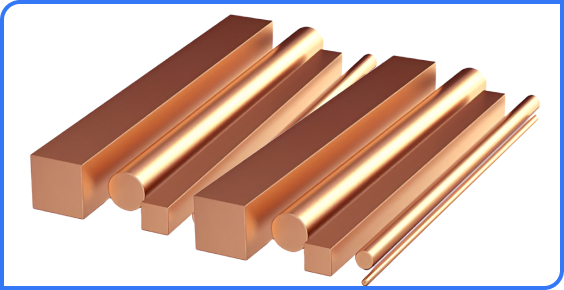

| CuNi Rods / Bars | Round, Hex, Square | |

| CuNi Fittings | Elbows, Tees, Reducers, Couplings | |

| Material Options | Copper Nickel Grades | CuNi 90/10, CuNi 70/30 |

| Other Alloys | – | Monel-CuNi alloys, customized grades available |

| Standards & Certifications | ASTM | ASTM B111, ASTM B466, ASTM B165 |

| ASME / ANSI | ASME B36.10, ASME B36.19 | |

| European Standards | EN 12451, EN 1652 | |

| Certifications | ISO 9001, PED 2014/68/EU, NACE MR0175 | |

| Design Features | Wall Thickness | As per ASTM / EN / ASME, customized options available |

| End Connections | Plain Ends, Beveled Ends | |

| Tolerance | As per ASTM / ASME / EN standards | |

| Coating & Surface Finish | Anti-Corrosion Coating | Passivation, Oxide Layer |

| Optional Coatings | PTFE, PVD, Electroplating | |

| Surface Finish | Mill Finish, Pickled, Polished, Bead Blasted | |

| Testing & Inspection | Pressure Testing | Hydrostatic, Pneumatic |

| Non-Destructive Testing | Radiography (RT), Ultrasonic (UT), Dye Penetrant (DPT) | |

| Destructive Testing | Tensile, Hardness, Impact |

Dimensions

| Product Type | Nominal Size / Diameter (mm) | Wall Thickness (mm) | Width (mm) | Length (mm) | Weight (kg/m) | Tolerance |

|---|---|---|---|---|---|---|

| CuNi Pipes (ERW / Seamless) | 10 – 500 | 1 – 25 | – | 6 – 12 m standard | 0.2 – 400 | ±0.1 – ±0.5 mm |

| CuNi Sheets / Plates | 10 × 10 – 500 × 500 | 1 – 50 | 100 – 2000 | 1000 – 6000 | 2 – 150 | ±0.2 – ±1 mm |

| CuNi Rods / Bars (Round) | 10 – 200 | – | – | 1000 – 6000 | 0.2 – 25 | ±0.1 – ±0.5 mm |

| CuNi Rods / Bars (Hex) | 10 – 150 | – | 10 – 150 | 1000 – 6000 | 0.15 – 20 | ±0.1 – ±0.5 mm |

| CuNi Rods / Bars (Square) | 10 – 150 | – | 10 – 150 | 1000 – 6000 | 0.15 – 20 | ±0.1 – ±0.5 mm |

| CuNi Fittings (Elbows / Tees / Reducers / Couplings) | DN 10 – DN 500 | As per ASME / ASTM | – | – | As per size | ±0.2 – ±1 mm |

Mechanical Properties

| Property | Value | Unit / Standard |

|---|---|---|

| Tensile Strength | 250 – 450 | MPa (CuNi 90/10, CuNi 70/30) |

| Yield Strength | 100 – 300 | MPa |

| Hardness | 60 – 160 | HB (Brinell) |

| Elongation | ≥ 20 – 40 | % |

| Density | 8.9 – 8.95 | g/cm³ |

| Impact Toughness | ≥ 20 – 60 | J (Charpy, grade-dependent) |

| Modulus of Elasticity (E) | 120 – 150 | GPa |

| Fatigue Strength | 150 – 300 | MPa |

| Corrosion Resistance | Excellent in seawater | – |

| Thermal Conductivity | 30 – 50 | W/m·K |

| Coefficient of Thermal Expansion | 16 – 18 ×10⁻⁶ | /°C |

| Yield Ratio (YS/UTS) | 0.35 – 0.65 | – |

| Poisson’s Ratio | 0.31 – 0.34 | – |

| Brinell Hardness Range | 60 – 160 | HB |

| Surface Finish | Mill, Polished, Pickled | – |

| Welding Type | TIG, MIG, Resistance | – |

| Operating Temperature Range | -50 to 300 | °C (grade-dependent) |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500 | ASME B16.5 Standards |

Chemical Composition

| Element | Copper Nickel 90/10 (%) | Copper Nickel 70/30 (%) |

|---|---|---|

| Copper (Cu) | 88.6 min | 65.0 – 70.0 |

| Nickel (Ni) + Cobalt (Co) | 9.0 – 11.0 | 29.0 – 33.0 |

| Iron (Fe) | 1.5 max | 0.4 – 1.0 |

| Manganese (Mn) | 1.0 max | 1.0 max |

| Zinc (Zn) | 0.5 max | 1.0 max |

| Lead (Pb) | 0.02 max | 0.02 max |

| Carbon (C) | 0.05 max | 0.05 max |

| Phosphorus (P) | 0.02 max | 0.02 max |

| Sulfur (S) | 0.02 max | 0.02 max |

| Others (Total) | 0.30 max | 0.30 max |

| Remaining Element | Balance Cu | Balance Cu |

Applications of Copper Nickel

Construction &

Infrastructure

Automotive & Heavy

Equipment

Manufacturing &

Fabrication

Medical & Laboratory

Equipment

Electrical &

Electronics Assembly

Oil, Gas & Petrochemical

Installations

Do you have questions?

70/30 has higher nickel content, offering better strength and corrosion resistance, while 90/10 is more cost-effective and easier to fabricate.

Yes. Its biofouling resistance and antimicrobial properties make it ideal for drinking water applications.

Yes, it can be welded using standard techniques such as TIG, MIG, and arc welding.

It has natural antifouling properties due to copper content, deterring algae, barnacles, and other marine organisms.