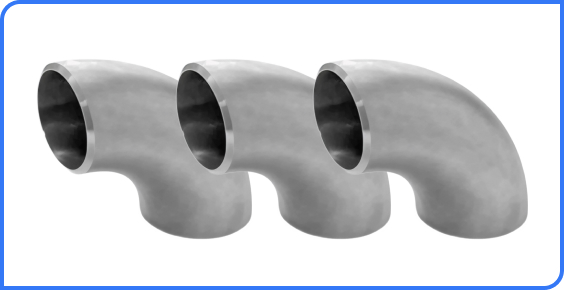

Buttweld Elbow

What is a Buttweld Elbow?

A Buttweld Elbow is a critical buttweld pipe fitting used to change the direction of flow in a piping system—typically at 45° or 90° angles. Welded directly to the pipe, it offers a smooth, permanent, and leak-proof transition, ensuring optimal flow with minimal turbulence or pressure drop.

Asiad Steel Industries is a leading manufacturer, supplier, and exporter of premium-quality Buttweld Elbows in various sizes, grades, and finishes, offering reliable piping solutions designed to ensure smooth directional flow across diverse industries worldwide.

Key Features

Leak-Proof

Jointing

Durable

Construction

High Pressure

Resistance

Wide

Compatibility

Corrosion

Resistant

Specifications

| Specification Category | Parameter / Feature | Details / Options |

|---|---|---|

| Size Range | Nominal Size | ½” to 48″ (custom sizes available) |

| Pressure Ratings | ANSI / ASME Class | Class 150, 300, 600, 900, 1500, 2500 |

| PN Ratings | PN6, PN10, PN16, PN25, PN40, PN64 | |

| Product Types | Butt Weld Elbow | 45°, 90°, 180° |

| Material Options | Carbon Steel | ASTM A234 WPB, ASTM A420 WPL6 |

| Stainless Steel | ASTM A403 WP304, WP316, WP321, WP347 | |

| Alloy Steel | ASTM A234 WP5, WP9, WP11, WP22 | |

| Other Alloys | Monel, Inconel, Titanium | |

| Standards & Certifications | ASTM | ASTM A234, ASTM A403 |

| ASME / ANSI | ASME B16.9, ANSI B16.9 | |

| MSS | MSS SP-75, MSS SP-43 | |

| European Standards | EN 10253-1, EN 10222 | |

| Certifications | ISO 9001, PED 2014/68/EU, NACE MR0175, CE Marked | |

| Design Features | Wall Thickness | As per schedule 40, 80, 160 or customized |

| End Connections | Butt Weld Ends | |

| Pressure Class | 2000#, 3000#, 6000#, 9000# | |

| Tolerance | Dimensional Tolerance | As per ASME B16.9 / B16.28 |

| Coating & Surface Finish | Anti-Corrosion Coating | Passivation, Epoxy Coating, Zinc Plated |

| Surface Finish | Mill Finish, Polished, Bead Blasted, Pickled | |

| Testing & Inspection | Pressure Testing | Hydrostatic, Pneumatic |

| Non-Destructive Testing | Radiography (RT), Ultrasonic (UT), Dye Penetrant (DPT), Magnetic Particle (MPI) | |

| Destructive Testing | Tensile, Hardness, Impact, Flattening |

Dimensions

| Fitting Type | Nominal Size (NPS) | Outside Diameter (OD) | Wall Thickness (Schedule) | Center-to-End (L) | Weight per Piece |

|---|---|---|---|---|---|

| Butt Weld Elbow (90°) | ½” | 21.3 mm | Schedule 40, 80 | 50 mm | 150g |

| Butt Weld Elbow (90°) | ¾” | 26.7 mm | Schedule 40, 80 | 60 mm | 200g |

| Butt Weld Elbow (90°) | 1″ | 33.4 mm | Schedule 40, 80 | 70 mm | 300g |

| Butt Weld Elbow (90°) | 1½” | 48.3 mm | Schedule 40, 80 | 85 mm | 500g |

| Butt Weld Elbow (90°) | 2″ | 60.3 mm | Schedule 40, 80 | 100 mm | 800g |

| Butt Weld Elbow (90°) | 2½” | 73.0 mm | Schedule 40, 80 | 120 mm | 1.2kg |

| Butt Weld Elbow (90°) | 3″ | 88.9 mm | Schedule 40, 80 | 140 mm | 1.5kg |

| Butt Weld Elbow (90°) | 4″ | 114.3 mm | Schedule 40, 80 | 160 mm | 2.0kg |

Mechanical Properties

| Property | Value | Unit / Standard |

|---|---|---|

| Tensile Strength | 485 – 750 | MPa (Carbon Steel, Stainless Steel, Alloy Steel) |

| Yield Strength | 170 – 450 | MPa |

| Hardness | 120 – 200 | HB (Brinell) |

| Elongation | ≥ 20 – 30 | % |

| Density | 7.8 – 8.0 | g/cm³ (Carbon Steel), 7.9 – 8.0 g/cm³ (Stainless Steel) |

| Impact Toughness | ≥ 27 – 70 | J (Charpy, grade-dependent) |

| Modulus of Elasticity (E) | ~200 | GPa |

| Fatigue Strength | 250 – 450 | MPa |

| Corrosion Resistance | Good to Excellent (SS > CS > Alloy Steel) | – |

| Thermal Conductivity | 15 – 50 | W/m·K |

| Coefficient of Thermal Expansion | 11 – 17 ×10⁻⁶ | /°C |

| Yield Ratio (YS/UTS) | 0.40 – 0.65 | – |

| Poisson’s Ratio | 0.27 – 0.30 | – |

| Brinell Hardness Range | 120 – 200 | HB |

| Surface Finish | Mill Finish, Pickled, Polished, Bead Blasted | – |

| Welding Type | Butt Weld Ends | – |

| Operating Temperature Range | -46 to 600 | °C (material-dependent) |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500 | ASME B16.9 / B16.28 |

Chemical Composition

| Element | SS 304 | SS 304L | SS 316 | SS 316L |

|---|---|---|---|---|

| Chromium (Cr) | 18.0 – 20.0 | 18.0 – 20.0 | 16.0 – 18.0 | 16.0 – 18.0 |

| Nickel (Ni) | 8.0 – 10.5 | 8.0 – 12.0 | 10.0 – 14.0 | 10.0 – 14.0 |

| Carbon (C) | ≤ 0.08 | ≤ 0.03 | ≤ 0.08 | ≤ 0.03 |

| Manganese (Mn) | ≤ 2.00 | ≤ 2.00 | ≤ 2.00 | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 | ≤ 0.045 | ≤ 0.045 | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 |

| Iron (Fe) | Balance | Balance | Balance | Balance |

| Molybdenum (Mo) | — | — | 2.0 – 3.0 | 2.0 – 3.0 |

Applications of Buttweld Elbows

Construction &

Infrastructure

Automotive & Heavy

Equipment

Manufacturing &

Fabrication

Medical & Laboratory

Equipment

Electrical &

Electronics Assembly

Oil, Gas & Petrochemical

Installations

Do you have questions?

Long radius (LR) elbows have a smoother bend for better flow; short radius (SR) elbows are more compact but create more turbulence.

Yes. We manufacture elbows in custom angles and radii as per project specifications.

TIG or MIG welding is typically used to join elbows to pipes for seamless installation.

Yes. When made from SS 304/316L with polished interiors, elbows are suitable for food & pharma use.