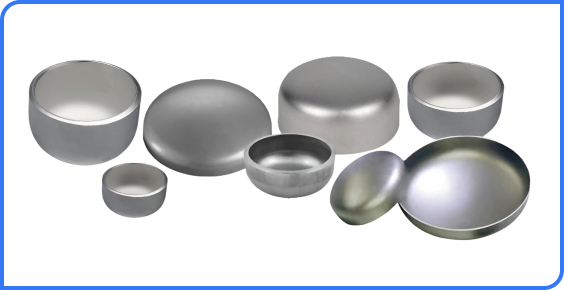

Buttweld Cap

What is a Buttweld Cap?

A Buttweld Cap is a pipe fitting used to seal the end of a pipe or pressure vessel. It is welded to the pipe end to stop the flow of fluid or gas, acting as a permanent barrier. These caps are commonly used for pipe termination, test heads, pressure holding, or future expansion.

Buttweld caps are essential in oil & gas, petrochemical, food processing, marine, and structural piping systems, ensuring protection from contaminants, corrosion, and mechanical damage.

Key Features

Leak-Proof

Jointing

Durable

Construction

High Pressure

Resistance

Wide

Compatibility

Corrosion

Resistant

Specifications

| Specification Category | Parameter / Feature | Details / Options |

|---|---|---|

| Size Range | Nominal Size | ½” to 48″ (custom sizes available) |

| Pressure Ratings | ANSI / ASME Class | Class 150, 300, 600, 900, 1500, 2500 |

| PN Ratings | PN6, PN10, PN16, PN25, PN40, PN64 | |

| Product Types | Butt Weld Cap | Standard, End Cap, Domed Cap |

| Material Options | Carbon Steel | ASTM A234 WPB, ASTM A420 WPL6 |

| Stainless Steel | ASTM A403 WP304, WP316, WP321, WP347 | |

| Alloy Steel | ASTM A234 WP5, WP9, WP11, WP22 | |

| Other Alloys | Monel, Inconel, Titanium | |

| Standards & Certifications | ASTM | ASTM A234, ASTM A403 |

| ASME / ANSI | ASME B16.9, ANSI B16.9 | |

| MSS | MSS SP-75, MSS SP-43 | |

| European Standards | EN 10253-1, EN 10222 | |

| Certifications | ISO 9001, PED 2014/68/EU, NACE MR0175, CE Marked | |

| Design Features | Wall Thickness | Schedule 40, Schedule 80, Schedule 160 |

| End Connections | Butt Weld Ends | |

| Pressure Class | 2000#, 3000#, 6000#, 9000# | |

| Tolerance | Dimensional Tolerance | As per ASME B16.9 / B16.28 |

| Coating & Surface Finish | Anti-Corrosion Coating | Passivation, Epoxy Coating, Zinc Plated |

| Surface Finish | Mill Finish, Polished, Pickled, Bead Blasted | |

| Testing & Inspection | Pressure Testing | Hydrostatic, Pneumatic |

| Non-Destructive Testing | Radiography (RT), Ultrasonic (UT), Dye Penetrant (DPT), Magnetic Particle (MPI) | |

| Destructive Testing | Tensile, Hardness, Impact, Flattening |

Mechanical Properties

| Property | Value | Unit / Standard |

|---|---|---|

| Tensile Strength | 485 – 750 | MPa (Carbon Steel, Stainless Steel, Alloy Steel) |

| Yield Strength | 170 – 450 | MPa |

| Hardness | 120 – 200 | HB (Brinell) |

| Elongation | ≥ 20 – 30 | % |

| Density | 7.8 – 8.0 | g/cm³ (Carbon Steel), 7.9 – 8.0 g/cm³ (Stainless Steel) |

| Impact Toughness | ≥ 27 – 70 | J (Charpy, grade-dependent) |

| Modulus of Elasticity (E) | ~200 | GPa |

| Fatigue Strength | 250 – 450 | MPa |

| Corrosion Resistance | Good to Excellent (SS > CS > Alloy Steel) | – |

| Thermal Conductivity | 15 – 50 | W/m·K |

| Coefficient of Thermal Expansion | 11 – 17 ×10⁻⁶ | /°C |

| Yield Ratio (YS/UTS) | 0.40 – 0.65 | – |

| Poisson’s Ratio | 0.27 – 0.30 | – |

| Brinell Hardness Range | 120 – 200 | HB |

| Surface Finish | Mill Finish, Pickled, Polished, Bead Blasted | – |

| Welding Type | Butt Weld Ends | – |

| Operating Temperature Range | -46 to 600 | °C (material-dependent) |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500 | ASME B16.9 / B16.28 |

Chemical Composition

| Element | SS 304 | SS 304L | SS 316 | SS 316L |

|---|---|---|---|---|

| Chromium (Cr) | 18.0 – 20.0 | 18.0 – 20.0 | 16.0 – 18.0 | 16.0 – 18.0 |

| Nickel (Ni) | 8.0 – 10.5 | 8.0 – 12.0 | 10.0 – 14.0 | 10.0 – 14.0 |

| Carbon (C) | ≤ 0.08 | ≤ 0.03 | ≤ 0.08 | ≤ 0.03 |

| Manganese (Mn) | ≤ 2.00 | ≤ 2.00 | ≤ 2.00 | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 | ≤ 0.045 | ≤ 0.045 | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 |

| Iron (Fe) | Balance | Balance | Balance | Balance |

| Molybdenum (Mo) | — | — | 2.0 – 3.0 | 2.0 – 3.0 |

Applications of Buttweld Cap

Construction &

Infrastructure

Automotive & Heavy

Equipment

Manufacturing &

Fabrication

Medical & Laboratory

Equipment

Electrical &

Electronics Assembly

Oil, Gas & Petrochemical

Installations

Do you have questions?

It permanently seals the end of a pipe, preventing leakage or environmental exposure.

No, they are welded and permanent. For removable ends, threaded caps or flanged blanks are used.

Yes, pipe caps are ideal for pressure testing and closure during commissioning.

Buttweld caps are manufactured as per ASME B16.9, ASME B16.28, and EN standards, and are available in a wide range of nominal pipe sizes and schedules to suit industrial piping systems.