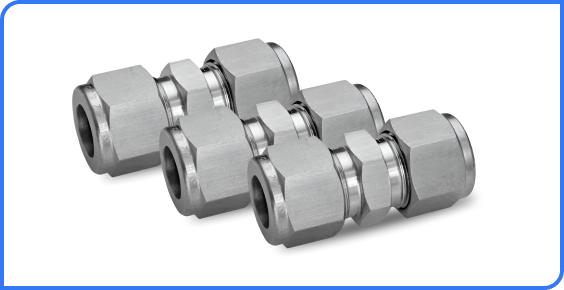

Instrument Union

What are Instrument Unions?

Instrument unions are two-piece fittings used to securely join two tubes or pipes in high-precision fluid systems. These fittings allow for easy disconnection and reassembly without disturbing the overall pipeline, making them ideal for instrumentation, analytical, and control systems.

Asiad Steel Industries is a reputed supplier and exporter of instrument unions known for leak-proof performance, pressure handling, and resistance to vibration or thermal expansion.

Key Features

Leak-Proof

Jointing

Durable

Construction

Easy Installation

& Removal

Wide

Compatibility

Corrosion

Resistant

Specifications

| Specification Category | Parameter / Feature | Details / Options |

|---|---|---|

| Size Range | Tube OD Sizes | 1/8” to 2” (3 mm to 50 mm) |

| Pressure Ratings | Working Pressure | Up to 6000 psi (414 bar) depending on size & material |

| Temperature Ratings | -196°C to 600°C (material-dependent) | |

| Fitting Types | Instrument Fittings | Union (Straight Union, Reducing Union, Bulkhead Union, Union Elbow, Union Tee, Union Cross) |

| Material Options | Stainless Steel | SS 304, SS 304L, SS 316, SS 316L |

| Standards & Certifications | ASME / ANSI | ASME B31.3, ASME B16.11 (applicable for fittings) |

| ASTM | ASTM A276, ASTM A479 (for SS bars/rods), ASTM A182 (for forgings) | |

| European Standards | EN 10272 (SS Bars & Rods), DIN 2353 (applicable for instrumentation) | |

| Certifications | ISO 9001, PED 2014/68/EU, NACE MR0175, IBR Approved | |

| Design Features | Connection Type | Double Ferrule Compression, Single Ferrule (on request) |

| End Connections | Tube OD to Tube OD, Tube OD to Male/Female NPT/BSP Threads | |

| Tolerance | As per ASME / ASTM standards | |

| Coating & Surface Finish | Surface Finish | Machined, Pickled, Polished, Passivated |

| Testing & Inspection | Pressure Testing | Hydrostatic, Pneumatic |

| Non-Destructive Testing | Ultrasonic (UT), Dye Penetrant (DPT) | |

| Destructive Testing | Tensile, Hardness |

Dimensions

| Tube OD (mm / inch) | Thread Size | Across Flats (AF, mm) | Overall Length (L, mm) | Pressure Rating |

|---|---|---|---|---|

| 3 mm (1/8″) | 1/8″ NPT / BSP | 12 – 14 | 25 – 28 | Up to 6000 psi |

| 6 mm (1/4″) | 1/4″ NPT / BSP | 14 – 17 | 30 – 33 | Up to 6000 psi |

| 8 mm (5/16″) | 1/4″ NPT / BSP | 17 – 19 | 32 – 36 | Up to 6000 psi |

| 10 mm (3/8″) | 3/8″ NPT / BSP | 19 – 22 | 35 – 38 | Up to 6000 psi |

| 12 mm (1/2″) | 1/2″ NPT / BSP | 22 – 25 | 38 – 42 | Up to 6000 psi |

| 16 mm (5/8″) | 5/8″ NPT / BSP | 25 – 28 | 42 – 46 | Up to 6000 psi |

| 18 mm (3/4″) | 3/4″ NPT / BSP | 28 – 32 | 45 – 50 | Up to 6000 psi |

| 20 mm (7/8″) | 3/4″ NPT / BSP | 32 – 36 | 50 – 55 | Up to 6000 psi |

| 25 mm (1″) | 1″ NPT / BSP | 36 – 41 | 55 – 60 | Up to 6000 psi |

Mechanical Properties

| Property | Value | Unit / Standard |

|---|---|---|

| Tensile Strength | 515 – 620 | MPa (Stainless Steel 316 / 316L) |

| Yield Strength | 205 – 240 | MPa |

| Hardness | ≤ 200 | HB (Brinell, Annealed Condition) |

| Elongation | ≥ 35 | % |

| Density | 7.9 – 8.0 | g/cm³ |

| Impact Toughness | ≥ 100 | J (Charpy at Room Temp.) |

| Modulus of Elasticity (E) | ~200 | GPa |

| Fatigue Strength | 240 – 300 | MPa |

| Corrosion Resistance | Excellent in chloride, acidic & marine environments | – |

| Thermal Conductivity | 15 – 20 | W/m·K |

| Coefficient of Thermal Expansion | 16 ×10⁻⁶ | /°C |

| Yield Ratio (YS/UTS) | 0.38 – 0.45 | – |

| Poisson’s Ratio | 0.27 – 0.30 | – |

| Brinell Hardness Range | 140 – 200 | HB |

| Surface Finish | Smooth / Passivated / Electropolished (as required) | – |

| Connection Type | Double Ferrule / Compression (threaded or welded ends) | – |

| Operating Temperature Range | -196 to +400 | °C (material-dependent) |

| Pressure Rating | Up to 6000 psi (414 bar) | ASTM / ASME Standards |

Chemical Composition

| Element | SS 304 (%) | SS 304L (%) | SS 316 (%) | SS 316L (%) |

|---|---|---|---|---|

| Carbon (C) | ≤ 0.08 | ≤ 0.03 | ≤ 0.08 | ≤ 0.03 |

| Manganese (Mn) | ≤ 2.00 | ≤ 2.00 | ≤ 2.00 | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 | ≤ 0.045 | ≤ 0.045 | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 |

| Chromium (Cr) | 18.0 – 20.0 | 18.0 – 20.0 | 16.0 – 18.0 | 16.0 – 18.0 |

| Nickel (Ni) | 8.0 – 10.5 | 8.0 – 12.0 | 10.0 – 14.0 | 10.0 – 14.0 |

| Molybdenum (Mo) | — | — | 2.0 – 3.0 | 2.0 – 3.0 |

| Nitrogen (N) | — | — | ≤ 0.10 | ≤ 0.10 |

| Iron (Fe) | Balance | Balance | Balance | Balance |

Applications of Instrument Unions

Construction &

Infrastructure

Automotive & Heavy

Equipment

Manufacturing &

Fabrication

Medical & Laboratory

Equipment

Electrical &

Electronics Assembly

Oil, Gas & Petrochemical

Installations

Do you have questions?

Yes, our unions are vibration-resistant and suitable for demanding installations like offshore rigs and mobile equipment.

SS 316, Hastelloy, and Alloy 20 are recommended for aggressive environments.

Yes, provided they are not physically damaged or excessively worn, they can be reused.

We offer both complete union assemblies (body + ferrules + nuts) and components individually.