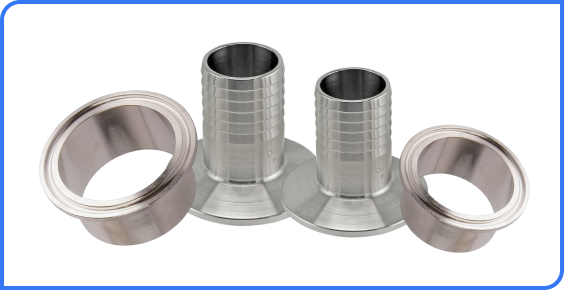

TC Ferrule

What are TC Ferrules?

A TC Ferrule (Tri-Clamp Ferrule) is a crucial connection component in sanitary piping systems, providing a smooth, secure interface between pipes and fittings. These ferrules are welded onto process lines or vessels and allow for quick, clamp-based assembly using gaskets and tri-clamp connectors. Used extensively in food processing, beverage, dairy, biotech, and pharmaceutical industries.

Asiad Steel Industries is a trusted supplier of premium-quality TC Ferrules in various sizes, surface finishes, and stainless steel grades.

Key Features

Leak-Proof

Jointing

Sanitary

Design

Easy to

Clean

Standards

Compliant

Corrosion

Resistant

Types of TC Ferrule

Specifications

| Specification Category | Parameter / Feature | Details / Options |

|---|---|---|

| Size Range | Ferrule Sizes | ½” to 6” (DN15 – DN150) |

| Tube OD Compatibility | 12.7 mm to 152.4 mm (as per sanitary tube sizes) | |

| Types of TC Ferrules | TC Ferrule Male | Suitable for secure clamp connections in hygienic pipelines |

| TC Ferrule Female | Designed for female-end sanitary fittings | |

| TC Ferrule Socket Weld | For socket-weld pipe connections | |

| TC Ferrule Butt Weld | For seamless buttweld integration | |

| TC Hose Ferrule | Designed for flexible sanitary hose fittings | |

| Material Options | Stainless Steel | SS 304, SS 304L, SS 316, SS 316L |

| Standards & Certifications | ASME / ANSI | ASME BPE |

| ASTM | ASTM A270 (Sanitary Tubing), ASTM A182 (Forged Ferrules) | |

| European Standards | DIN 32676, ISO 1127 | |

| Certifications | ISO 9001, 3A Sanitary Standards, PED 2014/68/EU | |

| Design Features | Ferrule Length | Short Weld, Long Weld, Custom Lengths |

| Thickness | 1.0 mm to 3.0 mm (size dependent) | |

| End Connection | Clamp-End, Weld-End, Hose-End | |

| Surface Finish | ID & OD polished to Ra ≤ 0.8 μm | |

| Coating & Surface Finish | Anti-Corrosion Coating | Not required for stainless steel |

| Surface Treatment | Polished, Electro-Polished, Passivated | |

| Testing & Inspection | Dimensional Testing | 100% gauge-verified for perfect clamp fit |

| Pressure Testing | Hydrostatic testing (for weld ferrules) | |

| Non-Destructive Testing | Visual & Dye Penetrant Testing for weld integrity | |

| Documentation | MTC 3.1 (EN 10204) available on request |

Dimensions

| Nominal Pipe Size (NPS / DN) | Outer Diameter (OD) mm | Inner Diameter (ID) mm | Wall Thickness (mm) | Length (L) mm | Clamp Size (inch) | Remarks |

|---|---|---|---|---|---|---|

| ½” (DN15) | 21.3 | 15 | 3.15 | 25 | ½” | Standard ferrule |

| ¾” (DN20) | 26.9 | 20 | 3.68 | 28 | ¾” | Standard ferrule |

| 1” (DN25) | 33.7 | 25 | 4.19 | 30 | 1” | Standard ferrule |

| 1½” (DN40) | 48.3 | 40 | 4.78 | 38 | 1½” | Standard ferrule |

| 2” (DN50) | 60.3 | 50 | 5.54 | 45 | 2” | Standard ferrule |

| 2½” (DN65) | 73 | 65 | 5.54 | 50 | 2½” | Standard ferrule |

| 3” (DN80) | 88.9 | 80 | 6.02 | 55 | 3” | Standard ferrule |

| 4” (DN100) | 114.3 | 100 | 6.55 | 65 | 4” | Standard ferrule |

| 6” (DN150) | 168.3 | 150 | 7.11 | 80 | 6” | Standard ferrule |

| 8” (DN200) | 219.1 | 200 | 8.18 | 100 | 8” | Standard ferrule |

| 10” (DN250) | 273 | 250 | 8.56 | 120 | 10” | Standard ferrule |

| 12” (DN300) | 323.9 | 300 | 9.53 | 140 | 12” | Standard ferrule |

Mechanical Properties

| Property | Value | Unit / Standard |

|---|---|---|

| Tensile Strength | 485 – 750 | MPa (Stainless Steel) |

| Yield Strength | 170 – 450 | MPa |

| Hardness | 120 – 200 | HB (Brinell) |

| Elongation | ≥ 20 – 30 | % |

| Density | 7.8 – 8.0 | g/cm³ |

| Impact Toughness | ≥ 27 – 70 | J (Charpy, grade-dependent) |

| Modulus of Elasticity (E) | ~200 | GPa |

| Fatigue Strength | 250 – 450 | MPa |

| Corrosion Resistance | Excellent | – |

| Thermal Conductivity | 15 – 50 | W/m·K |

| Coefficient of Thermal Expansion | 11 – 17 ×10⁻⁶ | /°C |

| Yield Ratio (YS/UTS) | 0.40 – 0.65 | – |

| Poisson’s Ratio | 0.27 – 0.30 | – |

| Brinell Hardness Range | 120 – 200 | HB |

| Surface Finish | Serrated / Stock / Smooth finish per ASME B16.5 | – |

| Welding Type | Butt-welded or Slip-on (depending on piping system) | – |

| Operating Temperature Range | -46 to 600 | °C (material-dependent) |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500 | ASME B16.5 Standards |

Chemical Composition

| Element | SS 304 (%) | SS 304L (%) | SS 316 (%) | SS 316L (%) |

|---|---|---|---|---|

| Carbon (C) | ≤ 0.08 | ≤ 0.03 | ≤ 0.08 | ≤ 0.03 |

| Manganese (Mn) | ≤ 2.00 | ≤ 2.00 | ≤ 2.00 | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 | ≤ 0.045 | ≤ 0.045 | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 |

| Chromium (Cr) | 18.0 – 20.0 | 18.0 – 20.0 | 16.0 – 18.0 | 16.0 – 18.0 |

| Nickel (Ni) | 8.0 – 10.5 | 8.0 – 12.0 | 10.0 – 14.0 | 10.0 – 14.0 |

| Molybdenum (Mo) | — | — | 2.0 – 3.0 | 2.0 – 3.0 |

| Nitrogen (N) | — | — | ≤ 0.10 | ≤ 0.10 |

| Iron (Fe) | Balance | Balance | Balance | Balance |

Applications of TC Ferrules

Dairy & Food Processing

Units

Beverage Plants

Pharmaceutical

Cosmetic & Personal

Care

Chemical & Enzyme

Production

Laboratory and Testing

Facilities

Do you have questions?

They are primarily designed for stainless steel pipes but can be adapted for compatible alloys. Ensure matching grades for hygiene and corrosion resistance.

Short weld ferrules are compact for limited-space applications, while long ferrules provide added welding surface and strength.

Yes, TC Ferrules are fully compatible with Clean-in-Place and Sterilize-in-Place protocols.

Absolutely. We manufacture ferrules in custom lengths, finishes, and wall thicknesses as per client specifications.