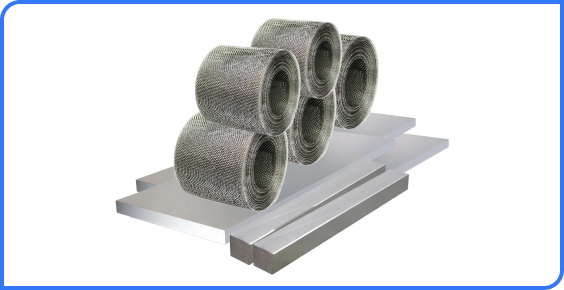

Stainless Steel Wire Mesh

What is Stainless Steel Wire Mesh?

Stainless Steel Wire Mesh is a versatile woven or welded mesh structure made from high-grade stainless steel wires. It offers excellent strength, corrosion resistance, and temperature endurance, making it suitable for filtration, separation, reinforcement, and screening applications across multiple industries.

Asiad Steel Industries is a leading manufacturer and supplier of high-quality Stainless Steel Wire Mesh in various weaves, sizes, and grades including SS 304, SS 316, SS 316L, and 310. Our wire meshes are precision-engineered for durability and performance in industrial, architectural, and commercial uses.

Key Features

- Corrosion Resistant – Withstands harsh chemicals, weather, and moisture exposure.

- High Strength & Flexibility – Offers robust mechanical integrity with formability.

- Multiple Weaving Styles – Available in plain weave, twill weave, Dutch weave, and more.

- Precise Filtration & Sizing – Accurate mesh openings for efficient screening and separation.

- Hygienic & Low Maintenance – Ideal for food-grade and sterile environments.

Types of Stainless Steel Wire Mesh

- Woven SS Wire Mesh

- Welded SS Wire Mesh

- Fine SS Filter Mesh

- Heavy-Duty Crimped Mesh

- Dutch Weave SS Mesh

- Architectural Mesh Panels

Specifications

Mechanical Properties

Chemical Composition

Equivalent Grades

Weight Chart

Specifications

| Property | Description |

|---|---|

| Mesh Size | 2 to 500 mesh (openings per inch) |

| Wire Diameter | 0.025 mm to 5 mm |

| Width Range | Up to 2000 mm (custom sizes available) |

| Length | 30 m standard rolls / custom cut lengths |

| Material Grades | SS 304, 304L, 316, 316L, 310, 321 |

| Weaving Types | Plain, Twill, Dutch, Crimped |

| Surface Treatment | Bright annealed, Electro-polished |

| Tolerances | ±2% for mesh count, ±3% for wire diameter |

| Property | Value |

|---|---|

| Tensile Strength | 550 – 750 MPa |

| Yield Strength | ≥ 210 MPa |

| Elongation | ≥ 40% |

| Hardness | ≤ 200 HB |

| Melting Point | 1400 – 1450°C |

| Element | Composition (%) |

|---|---|

| Chromium (Cr) | 16.0 – 20.0 |

| Nickel (Ni) | 8.0 – 14.0 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

| Standard | Equivalent Grade |

|---|---|

| ASTM | A580 / A276 |

| UNS | S30400 / S31600 / S31000 |

| EN | 1.4301 / 1.4401 / 1.4841 |

| JIS | SUS 304 / SUS 316 / SUS 310 |

| Mesh Count | Wire Dia (mm) | Weight (kg/m²) |

|---|---|---|

| 10 x 10 | 0.90 | 1.9 |

| 40 x 40 | 0.28 | 0.9 |

| 80 x 80 | 0.16 | 0.5 |

| 150 x 150 | 0.10 | 0.32 |

| 325 x 325 | 0.035 | 0.14 |

Applications of Stainless Steel Wire Mesh

Construction &

Infrastructure

Automotive & Heavy

Equipment

Manufacturing &

Fabrication

Medical & Laboratory

Equipment

Electrical &

Electronics Assembly

Oil, Gas & Petrochemical

Installations

Do you have questions?

What’s the difference between woven and welded wire mesh?

Woven mesh is interlaced like fabric and offers more flexibility, while welded mesh has fixed joints for higher strength and rigidity.

Can SS wire mesh be used in high-temperature applications?

Yes. SS 310 and 316 wire mesh can withstand temperatures up to 1100°C and resist oxidation.

Is stainless steel mesh suitable for outdoor use?

Absolutely. It resists rust and corrosion, making it ideal for external cladding, fencing, and ventilation.

Do you offer customized mesh sizes and shapes?

Yes. We can provide cut-to-size sheets, rolls, and even pre-fabricated mesh panels based on your project requirements.