Dairy Fittings and Valves

What are Dairy Fittings and Valves?

Dairy fittings and valves are precision-engineered components used to connect, control, and regulate fluid flow in sanitary process systems. Designed specifically for industries like dairy, food processing, beverages, pharmaceuticals, and biotechnology, these fittings ensure contamination-free fluid transfer with smooth, crevice-free interiors.

Asiad Steel Industries is a leading manufacturer, supplier, and exporter of high-quality dairy fittings and valves, delivering leak-proof performance, ease of cleaning, and long service life for sterile and hygienic applications.

Key Features

- Sanitary Design – Smooth surface finish and crevice-free interiors for hygiene-critical systems

- Easy to Clean – Designed for CIP (Clean-in-Place) and SIP (Sterilize-in-Place) procedures

- Corrosion Resistant – Made from SS 304, SS 316L for superior corrosion protection

- Leak-Proof Operation – Precision sealing for zero contamination or leakage

- Standards Compliant – Available in DIN, SMS, IDF, ISO, and 3A configurations

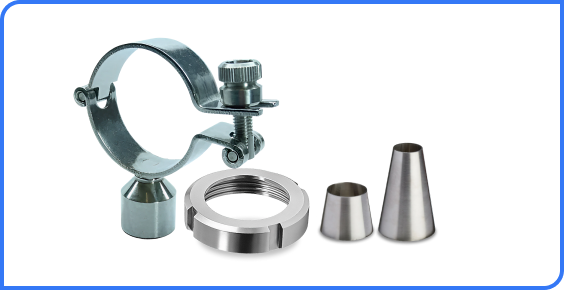

Types of Dairy Fittings and Valves

- Dairy Bends

- Dairy Tees

- Dairy Reducers

- Dairy Nipple

- Dairy Liner

- Dairy Nut

- Dairy Gasket

- Dairy Tube Expander

- Dairy Pipe Clamps

- Dairy SMS Union

- Butterfly Valves

- Ball Valves

- NRVs (Non-Return Valves)

Specifications

Mechanical Properties

Chemical Composition

Equivalent Grades

Weight Chart

Specifications

| Parameter | Specification |

|---|---|

| Size Range | ½" to 6" (DN15 to DN150) |

| Grades Available | SS 304, SS 316, SS 316L |

| Standards | SMS, DIN, IDF, ISO, 3A, ASTM |

| Surface Finish | Mirror Polish, Electro Polish, Matt Finish |

| End Connections | Butt Weld, Tri-Clamp, Threaded, Plain End |

| Operating Pressure | Up to 10 bar |

| Temperature Range | -10°C to +180°C |

| Property | Value |

|---|---|

| Tensile Strength | 485 – 620 MPa |

| Yield Strength | 170 – 310 MPa |

| Hardness | ≤ 200 HB |

| Elongation | ≥ 30% |

| Density | 7.9 g/cm³ |

| Element | Composition (%) |

|---|---|

| Chromium | 18.0 – 20.0 |

| Nickel | 8.0 – 10.5 |

| Carbon | ≤ 0.03 – 0.08 |

| Manganese | ≤ 2.00 |

| Silicon | ≤ 1.00 |

| Phosphorus | ≤ 0.045 |

| Sulfur | ≤ 0.030 |

| Iron | Balance |

| Standard | Equivalent Grade |

|---|---|

| ASTM | A240 / A276 – 304, 316L |

| DIN | 1.4301 / 1.4404 |

| EN | X5CrNi18-10 / X2CrNiMo17-12-2 |

| JIS | SUS 304 / SUS 316L |

| ISO | 3506-1 A2 / A4 |

| Component Type | Size | Weight per Piece (kg) |

|---|---|---|

| Dairy Bend | 1½" | 0.45 |

| Dairy Tee | 2" | 0.75 |

| Union Set (DIN) | 2½" | 1.10 |

| TC Clamp | 3" | 0.60 |

| Butterfly Valve | 4" | 2.80 |

| Sample Valve | 1" | 0.35 |

Do you have questions?

Are dairy fittings suitable for high-temperature cleaning processes?

Yes. They are designed for CIP/SIP cycles and can handle temperatures up to 180°C.

Do you supply dairy valves with certifications?

Absolutely. We offer valves with 3A, FDA, and ISO certificates upon request.

Can I get fittings in polished or electro-polished finishes?

Yes. Both mirror polish and electro-polish finishes are available for hygienic environments.

What’s the difference between SMS, DIN, and IDF unions?

These are different hygienic standards for union design. SMS is Scandinavian, DIN is German, and IDF is International Dairy Federation. We supply all variants.