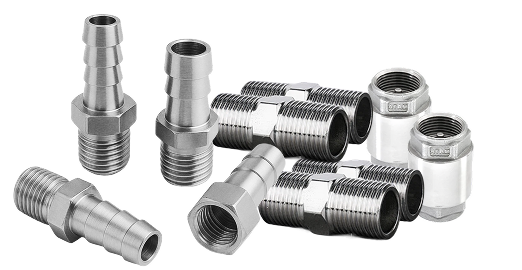

Investment Casting Fittings

What are Investment Casting Fittings?

Investment Casting Fittings are precision-engineered pipe fittings manufactured using the lost-wax investment casting process, which allows for intricate shapes, smooth surface finishes, and tight dimensional tolerances. This method is ideal for producing complex fittings with high consistency, especially for small-diameter, high-performance piping systems.

These fittings are used in sanitary, food-grade, pharmaceutical, marine, and instrumentation applications where appearance, accuracy, and corrosion resistance are as important as functionality. Investment casting supports production of fittings like elbows, tees, nipples, bushings, unions, sockets, and check nuts with minimal post-machining.

Key Features

- Securely Seals Pipe Ends – Provides tight closure for pipeline termination.

- Seamless & Welded Options – Designed for high-pressure applications.

- Wide Wall Compatibility – Fits SCH 10 to XXS pipe thicknesses.

- Reduces Stress & Corrosion – Enhances durability at pipe ends.

- Standards Certified – Manufactured per ASME, MSS, DIN, and EN norms.

Types of Investment Casting Fittings

- Threaded Elbow

- Tee

- Union

- Socket

- Hose Nipple

- Hex Nipple

- Bushing

- Check Nut

Specifications

Mechanical Properties

Chemical Composition

Equivalent Grades

Weight Chart

Specifications

| Parameter | Details |

|---|---|

| Sizes | ⅛" to 4" (DN6 to DN100) |

| Thread Types | BSP, NPT, BSPT, ISO Metric |

| End Connections | Threaded / Socket Weld / Butt Weld |

| Material Options | SS 304, SS 316, SS 316L, CF8M, Duplex Steel |

| Standards | ASME B16.11, MSS-SP-95, DIN 2950 |

| Tolerances | As per ISO 8062 / ASTM A743 |

| Property | Typical Value |

|---|---|

| Tensile Strength | 485 – 750 MPa |

| Yield Strength | 205 – 450 MPa |

| Elongation | 20% – 30% |

| Hardness | 125 – 250 HB |

| Working Temperature | -50°C to +600°C |

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Chromium (Cr) | 18.0 – 20.0 |

| Nickel (Ni) | 8.0 – 14.0 |

| Molybdenum (Mo) | 2.0 – 3.0 (for CF8M/316) |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

| Standard | Equivalent Grades |

|---|---|

| ASTM | A351 CF8 / CF8M, A743, A744 |

| ASME | B16.11 |

| MSS-SP | SP-95 |

| DIN | 2950 / 2955 |

| ISO | ISO 4144 / ISO 8062 |

| Fitting Type | Size (inches) | Weight per 100 pcs (kg) |

|---|---|---|

| Threaded Elbow | 1" | 12.80 |

| Threaded Tee | 1½" | 15.60 |

| Hex Nipple | 1" | 9.20 |

| Union (Beveled Seat) | 2" | 18.50 |

| Socket | ¾" | 9.40 |

| Check Nut | 1" | 6.10 |

Applications of Investment Casting Fittings

Construction &

Infrastructure

Automotive & Heavy

Equipment

Manufacturing &

Fabrication

Medical & Laboratory

Equipment

Electrical &

Electronics Assembly

Oil, Gas & Petrochemical

Installations

Do you have questions?

What makes investment casting better for fittings?

Investment casting enables precise shapes, minimal machining, and excellent surface finish, which are critical in sanitary and complex fluid systems.

Are these fittings available in duplex or super duplex grades?

Yes, we offer castings in Duplex, Super Duplex, and even Inconel or Hastelloy upon request.

Can these fittings be used in food-grade pipelines?

Absolutely. SS 304 and 316L cast fittings are widely used in hygienic processing units and come with mirror polishing options.

Do investment casting fittings meet international certifications?

Yes. Our fittings comply with ASME, DIN, ISO, and we offer MTCs and third-party inspection certificates upon request.